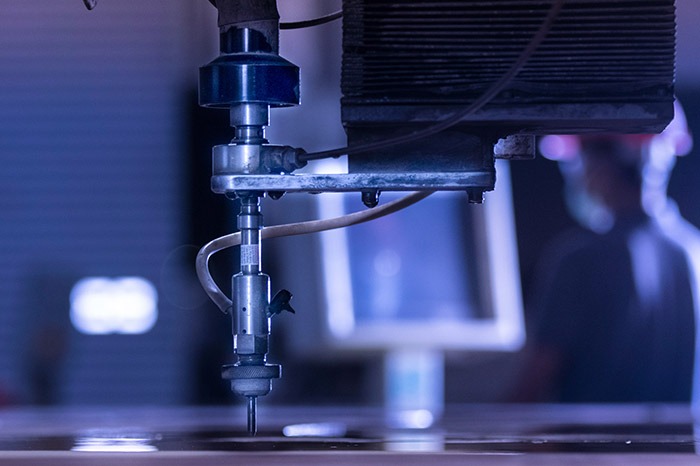

Different Uses & Benefits of Waterjet Metal Cutting

Waterjet metal cutting is one of the most versatile methods for precision metalworking. It is used in various industrial sectors to produce large sheets of reusable scrap metal. The process is not destructive to the material and does not create dangerous waste. It has a high cutting speed and is used for a variety of metal materials. It can also be used for flammable machining materials, such as rebar and sheet metal.

Helpful in making electronic parts:

The most important use for waterjet metal cutting is making electronic parts. This cutting process can cut through composites, aluminum, and hardened steel up to 25mm thick. It can also be used to make enclosures and robots. This method of cutting is widely used in industries around the world. However, it is not recommended for delicate and fragile materials. It is not recommended for thin sheets of metal since the high-pressure water can cause the abrasive stream to damage the material.

Useful for other materials:

Apart from metal parts, waterjet cutting is also useful for other materials. This method is flexible and versatile and can be applied to most kinds of materials. It is a very efficient and cost-effective way of manufacturing complex parts. It can also be used for heat-sensitive materials like aluminum and titanium. It is a cost-effective and flexible method of cutting. It is a reliable method of machining. For this purpose, it has become one of the most popular methods of metalworking.

Useful for different industries:

Apart from the various uses of water jet metal cutting, it is also widely used. It is a useful tool that can use for various applications. Its high precision and speed allow it to make intricate designs and logos. The control unit contains pre-installed programs that the user can use to ensure perfect cuts. When compared to other cutting methods, waterjet metal cutting requires little secondary finishing and is highly accurate.

You can modify it to meet specific needs:

Unlike traditional cutting methods, waterjet metal cutting has many advantages. It is a versatile tool that can easily be modified to meet specific needs. Moreover, it cuts various materials, including glass, rubber, and plastic. Using a high-pressure water jet, a high-speed stream of water erodes a narrow line in the material. Further, its flexibility makes it a preferred choice for a variety of different materials.